Edward Valves

High Performance for Critical Service Temperatures that can exceed 1000°F. Pressures surpassing 10 000 psi. In critical service conditions, you can’t take chances. You don’t just meet standards, you exceed them. That’s how Flowserve Edward forged and cast steel valves have become the specified choice for power plants, process facilities, and other high-temperature, high-pressure services.

Conservative Design

Flowserve Edward Valves takes a conservative approach to valve design. We meet all applicable codes and standards, but we go beyond that with finite element stress analysis of critical areas and rigorous proof testing. Edward valves are built to take punishment! And our extensive testing has also allowed us to develop extremely high flow efficiencies in all our valves. You’ll find other unique design advantages with our varied product lines, such as our Equiwedge® gate valves with a two-piece wedge gate assembly that adjusts automatically to any angular distortion of the body seats.

Precision Manufacturing

Edward Valves also exceeds industry standards on the factory floor. Our forged valves are produced on a fully automated line, with CNC machining centers providing precise process control. And we maximize cast steel quality by producing our valve body castings using a directional solidification process from patterns designed by our own technicians. This process ensures high-strength, void-free castings for uncompromised quality. Even with the most advanced equipment, we feel our people make the real difference. Our production personnel have an average of 20 years in the industry, and 15 years with Flowserve!

Lower Total Costs

Those tough standards have carried over into every valve we manufacture. We design and build our valves to last at least 40 years. That means not only are they tough, but they are designed with easy maintenance in mind.

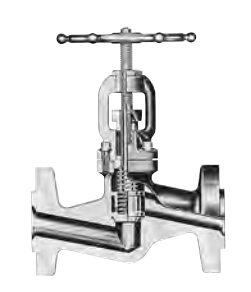

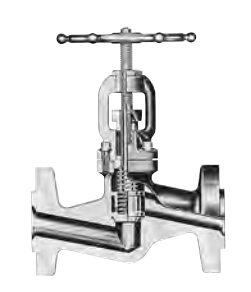

EDWARD 1028 GLOBE VALVE

Forged Steel Globe Valve Flanged Edward 1028 Standard Features Pressure Class 1500 (PN 260) Specs & Brochures

EDWARD 1046 GLOBE STOP CHECK VALVE

Stop Check Non-Return design, Spring loaded. Available in Globe Pattern. Edward 1046 Standard Features Pressure Class 1500 (PN 260)

EDWARD 1048 & 1048Y Y-PATTERN GLOBE VALVES

The Bolted Bonnet Y-Pattern Globe Valve is a durable, high-performance small bore globe valve that is forged and equipped with a bolted-bonnet design for improved maintenance. Edward 1048 & 1048Y

EDWARD 1068 & 1068Y Y-PATTERN GLOBE STOP CHECK VALVES

The Bolted Bonnet Y-Pattern Globe Valve is a durable, high-performance small bore globe valve that is forged and equipped with a bolted-bonnet design for improved maintenance. Edward 1068 & 1068Y

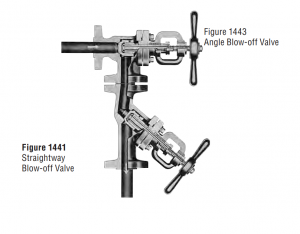

EDWARD 1441 GLOBE & 1443 ANGLE BLOW OFF VALVE

Edward 1441 Globe & 1443 Angle Blow Off Valve Standards Edward valves sold for blow-off service are designed and manufactured to comply with all Boiler Code criteria for valves used

EDWARD 1641 GLOBE & 1643 ANGLE BLOW OFF VALVE

Edward valves sold for blow-off service are designed and manufactured to comply with all Boiler Code criteria for valves used in these applications. Edward 1641 & 1643 Standard Features Pressure

Edward 1643 Blow Off Valve Angle

Edward valves sold for blow-off service are designed and manufactured to comply with all Boiler Code criteria for valves used in these applications. Edward 1643 Blow Off Valve Angle Standard

EDWARD 36124 & 36224 Y-PATTERN GLOBE VALVES – UNIVALVE

The Flowserve Univalve Y-Pattern Globe Valve is designed for maximum flow capacity and minimum leakage in high pressure, high temperature applications. EDWARD 36124 & 36224 Y-PATTERN GLOBE VALVES – UNIVALVE

EDWARD 36128 & 36228 Y-PATTERN GLOBE VALVES – UNIVALVE

The Flowserve Univalve Y-Pattern Globe Valve is designed for maximum flow capacity and minimum leakage in high-pressure, high-temperature applications. EDWARD 36128 & 36228 Y-PATTERN GLOBE VALVES – UNIVALVE STANDARDS FEATURES

EDWARD 66124 & 66224 Y-PATTERN GLOBE VALVES – UNIVALVE

The Flowserve Univalve Y-Pattern Globe Valve is designed for maximum flow capacity and minimum leakage in high pressure, high temperature applications. EDWARD 66124 & 66224 Y-Pattern Globe Valves – Univalve

EDWARD 66128 & 66228 Y-PATTERN GLOBE VALVES – UNIVALVE

The Flowserve Univalve Y-Pattern Globe Valve is designed for maximum flow capacity and minimum leakage in high pressure, high temperature applications. EDWARD 66128 & 66228 Y-PATTERN GLOBE VALVES – UNIVALVE

EDWARD 828 GLOBE & 829 ANGLE VALVE

Available in Globe and Angle Pattern Edward 828 & 829 Standard Features Pressure Class 600 (PN 110)

EDWARD 846 GLOBE STOP CHECK & 847 ANGLE STOP CHECK VALVE

Stop Check Non-Return design, Spring loaded. Available in Globe and Angle Pattern Edward 846 & 847 Standard Features Pressure Class 600 (PN 110) Specs & Brochures

EDWARD 848 & 848Y Y-PATTERN GLOBE VALVES

The Bolted Bonnet Y-Pattern Globe Valve is a durable, high-performance small-bore globe valve that is forged and equipped with a bolted-bonnet design for improved maintenance.

EDWARD 96124 & 96224 Y-PATTERN GLOBE VALVES – UNIVALVE

The Flowserve Univalve Y-Pattern Globe Valve is designed for maximum flow capacity and minimum leakage in high pressure, high temperature applications. EDWARD 66124 & 66224 Y-PATTERN GLOBE VALVES – UNIVALVE

EDWARD 96128 & 96228 Y-PATTERN GLOBE VALVES – UNIVALVE

The Flowserve Univalve Y-Pattern Globe Valve is designed for maximum flow capacity and minimum leakage in high pressure, high temperature applications. EDWARD 96128 & 96228 Y-PATTERN GLOBE VALVES – UNIVALVE

EDWARD FLEXIBLE SPLIT WEDGE GATE VALVES – EQUIWEDGE

A large bore gate valve with body-guided, split wedges, offers superior leak tightness and performance.

EDWARD FLEXIBLE SPLIT WEDGE GATE VALVES – EQUIWEDGE MAIN FEEDWATER ISOLATION VALVE

Compliant with ASME Section III and RCC-M design codes, this valve is the industry standard for fast-acting, reliable isolation of main steam or main feedwater lines.

EDWARD FLEXIBLE SPLIT WEDGE GATE VALVES – EQUIWEDGE MAIN STEAM ISOLATION VALVE

Compliant with ASME Section III and RCC-M design codes, the Flexible Split Wedge Gate Valve is the industry standard for fast-acting, reliable isolation of main steam or main feedwater lines.

EDWARD PISTON (LIFT) CHECK VALVES – UNIVALVE

The Univalve Piston Check Valve is reliably designed for high-temperature and high-pressure uses in a variety of environments.

EDWARD Y-PATTERN GLOBE VALVES – FLITE-FLOW

The Edward Flite-Flow Y-Pattern Globe Valve is designed for maximum flow capacity and minimum leakage in high-pressure, high-temperature applications. Available in cast (standard) and forged (optional) configurations.

TILTING DISK CHECK VALVES – EDWARD

The Edward Tilting Disk Check Valve is a large bore valve designed to close as quickly as possible, minimizing loud, damaging slamming and vibration noises caused by high-velocity reverse flow in high-pressure and high-temperature applications.