Materials: CS, SS, Monel®, Duplex and other exotic materials Seats: Metal and Soft Connections: 1/2” to 3/4” threaded, welded also available Pressure (max): M25: 6,000 psig (414 barg) M251: 10,000 psig (690 bar Temperature (max): M25: -70° to 1000°F (-57° to 538°C) M251: -70° to 500°F (-57° to 260°C)

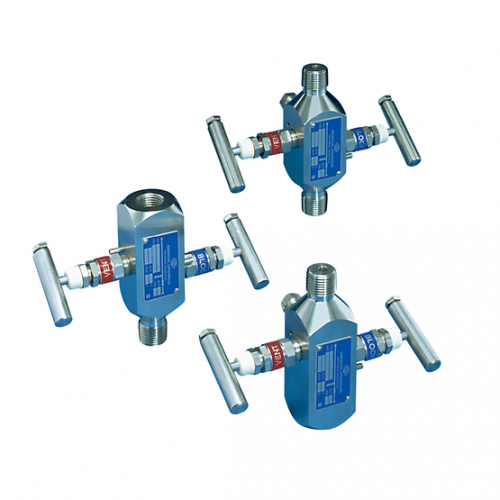

Tescom Block and Bleed Gauge Valves General Application

These valves enable gauges, pressure transmitters or switches to be installed and serviced reliably by reducing potential leak points. A threaded and plugged vent port enables the safe installation of exhaust piping/tubing on hazardous service.

Block and Bleed Gauge Valves Features:

- Compact design minimizes space requirements; low weight improves connection strength and reduces gauge whip.

- Minimal instrument installation components reduce costs and decrease possible leak points.

- Easy instrument check calibration using ¼” FNPT vent/test port.

- Ball end stem eliminates seat galling, provides bubble-tight shutoff and long life. Hardened, non-rotating ball ensures perfect alignment closure.

- Packing below threads prevents lubricant washout, thread corrosion, process contamination and eliminates galling.

- Easily adjustable packing decreases replacement downtime and increases valve life.

- Safety back seating prevents stem blowout or accidental removal and provides a metal-to-metal secondary stem seal while in the fully open position.

- Dust cover prevents lubricant washout and protects bonnet assembly from contaminants.

- ENC plated 316 SS prevents galling or freezing of stem threads.

- Rolled stem, bonnet and male NPT threads provide additional strength.

- Mirror stem finish in the packing area enables smooth operation and extends packing life.

- Metal-to-metal body-to-bonnet seal in constant compression prevents bonnet thread corrosion, eliminates possible tensile breakage and gives a reliable seal point.