Materials: CS, SS, Monel®, Hastelloy®, Duplex and other exotic materials Seats: Metal and Soft

Instrument Connections: 1/4” to 1/2” threaded or flange mounting

Process Connections: 1/4” to 1/2” threaded or flange mounting

Pressure (max): 6,000 psig [414 barg]

Temperature (max): 1,000°F [538°C]

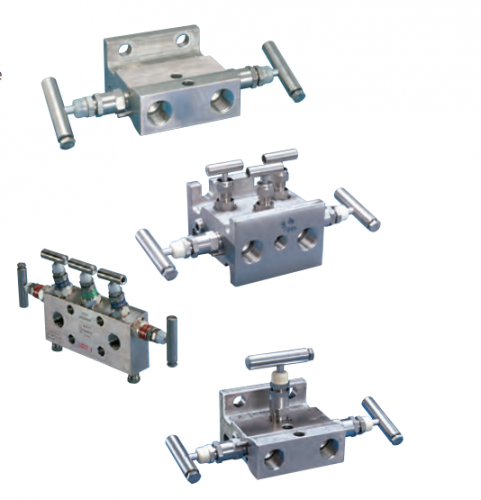

Anderson Greenwood has the largest and most innovative range of “differential pressure” flow and level manifolds available with models for virtually every type of D/P instrument. These include conventional three and five valve manifolds as well as purpose-designed models for special applications.

Features & Benefits:

- Compact design requires minimum space for operation and installation.

- Fewer leak points reduce leakage by having fewer parts to assemble.

- Free-swiveling ball end stem (metal seat) assures bubble-tight valve closure without seat galling.

- The AGCO Mount provides easy instrument removal. Direct bolting to the manifold allows the instrument to be removed independently of the piping. This facilitates repairs, service, and calibration.

- Immediate installation with AGCO Mount’s manifold, steam block, bracket, and all associated piping can be installed without the instrument at the time of plant construction.

- Secure mounting is provided by the AGCO Mount. Instrument piping stability is enhanced when directly supported by the pipe stand through the manifold.

- All valve threading is isolated. Packing is below stem threads, body-to-bonnet seal is below the threads eliminating process fluid corrosion.

- Less instrument damage with the AGCO Mount. The instrument can be safely warehoused until final “loop” checkout, reducing the chances of damage during construction.