Pressure Vacuum Relief Valves

Protectoseal, with the industry’s most trusted brands and an extensive range of technology, is a global leader of overpressure protection products for critical applications. Protectoseal delivers highly engineered equipment, application support and life cycle services to help assure optimum protection of our customer’s assets and employees. Protectoseal overpressure protection products are applied in a wide range of industries including oil and gas, petrochemical, chemical, and power generation and are supported by our sophisticated research and test facilities for steam, air, gas, and liquid.

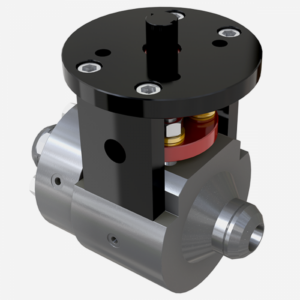

Cash A Series Pressure Regulators

Single seated and self-actuating compact diaphragm-type regulators covering a wide range of designs and operating pressures A series regulators are suitable for a variety of applications with water, air, oil,

Cash Valve B Series pressure regulators

Single seated, spring loaded, direct-acting diaphragm-type pressure-reducing and regulating valves for a broad range of services B series pressure-reducing valves and regulators include models suitable for air, water, steam, oil,

Cash Valve Series LS, Pressure Reducing and Regulating Valves

High-pressure single-seated, spring-loaded, direct-acting diaphragm type regulators for inlet pressures to 2400 psig (165.5 barg) Type LS Series regulators are recommended for use on high-pressure test rigs and pressure vessel

E-Series Relief Valve

Remington Valve E-Series relief valves provide security and overpressurization protection in an automated package.

Farris 2600 Relief Valve

Conforms to API 526 Full Nozzle Design Integral Cast Flanges Metal Seat with optional O-ring Balanced Bellows option Open Bonnet and Lever Assemblies option Adjustable Blowdown 2600L – Multiple Service

Farris 2700 Process Valve

Metal Seat with optional O-ring Balanced design option Flanged option Optional welding nipple and sanitary connections Farris 2700 General Specifications: Size 1/2” x 1” to 1-1/2” x 2-1/2” Orifice Areas

Farris 3800 Process Valve

Conforms to API 526 Snap Acting and Modulating Control Actuation Semi and Full Port Nozzle Design Typical Blowdown of 3-6% Farris 3800 General Specifications: Size 1” x 2” to 12”

Farris 4200 Steam Safety Valves

Flanged Spring Loaded Boiler Safety Valve Full nozzle design Open bonnet design One piece guide Low stem bearing point Temperature equalizing disc Heavy stainless steel lock screw studs Test Gag

Farris 6400 Steam Safety Valve

Flanged Spring Loaded Boiler Safety Valve Available in closed bonnet or exposed spring versions Hardened conical disc for extended seat life Full nozzle design Farris 6400 Steam Safety Valve Specifications:

Farris Smart Pressure Relief Valve

2600 Series Pressure Relief Valve Equipped with a Fisher 4320 Wireless Position Monitor WirelessHART Protocol Integrates into plants with existing Emerson Wireless Infrastructure Orifice Sizes D through U Retrofits available

Kunkle 6252 and 6254

Applications: Steam Boilers and Generators. Pressure Reducing Stations. Air/Gas Compressors – reciprocating or rotary. Pressure Vessels – including tanks, receivers, intercoolers, oil/gas separators, and lines. Pressure and Temperature LimitsModel 6252:

Kunkle Cast Iron Liquid Relief Valves Model 91, 218, 228

Pressure and Temperature Limits** Model 91: 5 psig to 400 psig; -20°F to 406°F Models 218, 228: 60 psig to 200 psig; -20°F to 406°F Pressure and Temperature Limits**Model 91:

Kunkle Liquid Relief Valve Model 20

Bronze construction, Pressure tight cap, MxF Ends Liquid relief service Sizes: 1/2 to 3 inch Range: 1 to 300 PSI Temp: -60 to 406 F Kunkle relief valve model Model

Kunkle Relief Valve Model 900: 910, 911, 917, 920,921,927

Applications: Air/gas compressors, intercoolers, aftercoolers. Liquid-filled pressure vessels/systems, ASME Section VIII (UV). Vacuum systems including pumps, tanks, and equipmentPressure vessels – containing gas, air, liquid, or steam, including tanks and

Kunkle Relief Valve Series 6000

Applications: Steam Boilers and Generators. Air/Gas Compressors – reciprocating or rotary – portable or stationary, intercoolers and aftercoolers. Pressure Vessels – containing steam, air, or non-hazardous gas. Including tanks, receivers,

No. 56000 Bubble-Tight <500 ppm Pressure Relief Vents

Series No. 56000, Bubble-Tight Series No. 56000, Bubble-Tight <500 ppm Pressure Relief Vents are designed and tested to address concerns about the leakage of fugitive emissions prior to set point,

Series 5200G Free Vent

The Protectoseal Series 5200G Free Vent provides open access to the tank’s vapor space and provides pressure and vacuum venting. Flange connection mounts to tank’s roof nozzle. The opening is

Series 54000 Spring Loaded Emergency Pressure Vents

Protectoseal Series 54000 Spring Loaded Emergency Pressure Vents provide emergency pressure relief for storage tanks as well as access for tank cleaning, inspection, and repair work. They are designed for

Series 8540G Aluminum End-of-Line Pressure / Vacuum Breather Vent

The NEW Series 8540G Improved Performance, Aluminum, End-of-Line Pressure / Vacuum Breather Vent provides quicker pressure pallet lift and improved flow performance at low overpressures just above the relief set

Series No. 16240 Vacuum Relief Vents

Protectoseal Series No. 16240 Vacuum Relief Vents are intended for use where only vacuum relief is required. They are designed to be side-mounted to the tank structure or piping. A

Series No. 17800 Pipe-Away Pressure Conservation Vent

Protectoseal Series No. 17800, Pipe-Away Pressure Conservation Vent, is intended for use where pressure relief is required and the relieving vapors must be piped away and not emitted into the

Series No. 18540 Pipe-Away Pressure / Vacuum Conservation Vent

Protectoseal Series No. 18540, Pipe-Away Pressure / Vacuum Conservation Vent, is designed to provide pressure and vacuum relief in applications that require hazardous vapors to be piped away, rather than

Series No. 51700 Hinged Emergency Pressure Manhole Cover Vents

Protectoseal Series No. 51700 Hinged Emergency Pressure Manhole Cover Vents provide emergency pressure relief for storage tanks that are exposed to an external fire. They are designed to open and

Series No. 52600 Emergency Pressure Vacuum Relief

Protectoseal Series No. 52600 provides both emergency pressure relief and vacuum relief when installed on the manhole opening of a storage tank. In emergency situations (external fire involvement of the

Series No. 53300 Emergency Pressure Manhole Cover Vents

Protectoseal Series No. 53300 Emergency Pressure Manhole Cover Vents provide emergency pressure relief for storage tanks as well as convenient access for tank cleaning, inspection, and repair work. They are

Series No. 6240 Vacuum Relief Vents

Protectoseal Series No. 6240 Vacuum Relief Vents are intended for use where only vacuum relief is required. A pallet in the vent housing retards air intake as the tank normally

Series No. 670E End-of-Line Deflagration Flame Arresters

Protectoseal Series No. 670E End-of-Line Deflagration Flame Arresters are installed where it is not necessary to conserve vapors but where low flash point liquids must be protected against fire and

Series No. 7800 Emergency Pressure Vents

Protectoseal Series No. 7800 Emergency Pressure Vents are designed to provide emergency relief capacity beyond that furnished by the operating vent on tanks. The Series No. 7800 vents do not

Series No. 830 Pressure / Vacuum Conservation Vent with Flame Arrester

Protectoseal Series No. 830, Pressure / Vacuum Conservation Vent with Flame Arrester, is designed to prevent costly evaporation losses, tank rupture due to overpressure, and collapse due to vacuum. The

Series No. 8540H End-of-Line Pressure/Vacuum Conservation Vent

The Protectoseal Series No. 8540H, End-of-Line Pressure / Vacuum Conservation Vent, is intended for use where both pressure and vacuum relief are required. The pallets in the vent housing allow