The Hydro-Guard® Automatic and S.M.A.R.T. Flushing product family offers industry-leading, reliable designs to address a range of utility needs and community concerns. Traditional routine flushing programs can mitigate community drinking water concerns related to taste, discoloration, or odor; however, manual hydrant flushing can be costly and time-consuming for utilities along with causing wear on the hydrant. Automated flushing programs can address these issues while also considering climate, environmental, installation, and community concerns. Each product series is available in a cold climate or warm climate edition and supports a range of popular bury depth options to ensure year-round performance in any distribution network. In addition, Hydro-Guard Automatic and S.M.A.R.T. Flushing Systems incorporate physical security and are UL-listed and certified to NSF/ANSI 372.

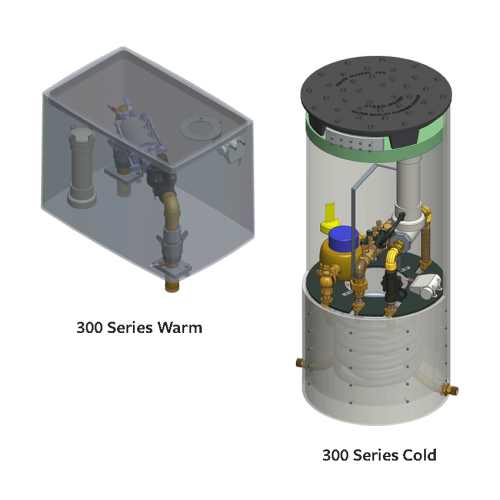

The Hydro-Guard® 300 Series Automatic Flushing System is ideal for distribution systems with problematic disinfectant residuals or where taste, color or odor issues lead to customer complaints. The below-ground design of the 300 Series system reduces the potential for freeze damage while allowing utilities to enhance water quality by flushing, collecting quality samples from the flushing system, and conducting flushing operations when water quality conditions warrant. The below-ground installation is aesthetically pleasing to customers who are opposed to having pedestal enclosures on their property, in addition to reducing customer complaints related to flush events and related water usage.

With the available Bluetooth controller, authorized operators can schedule up to 24 different flush events into the controller through a free K-Rain KRBL V2 app that can be added to most iOS or Android phones. Flush durations can range from one (1) minute to six (6) hours per programmed flush event. Where the use of a mobile app or Bluetooth is not permitted, the 300 Series can be equipped with a built-in NODE programmer. The NODE programmer allows for the scheduling of flush events multiple times per day, multiple times per week.

The 300 Series Automatic Flushing System is equipped with an OEM-installed Dechlorination System and an onsite, OEM-installed Sampling System to allow water quality samples to be drawn directly from the flushing system.

FEATURES:

- 300 Series Warm Climate

- 2-inch internal piping assembly with no lead brass

- Durable DFW meter vault, lockable

- Wilkins-Zurn DC valve backflow prevention

- Available Bury Depth: 24-inches

- 300 Series Cold Climate

- 1-inch Mueller Thermal Coil Meter Vault no kink coil technology allows tubing to be easily raised and lowered for operation and maintenance with no lead brass. Coil allows all flushing components to rest below frost depths for protection against frost damage.

- Wilkins-Zurn DC valve backflow prevention

- Includes a 2-inch-thick insulation pad to help maintain ground heat inside of the vault

- Available Bury Depths: 48-inches, 60-inches, 84-inches, and 108-inches

- Optional Pressure Monitoring for the measurement and reporting of critical pressures

- Available with a choice of 22.75-inch composite or cast lid

- Standard no-lead brass piping

- Glass-reinforced Nylon composite valve with flow adjustment, full port, and single-piece EPDM diaphragm

- OEM-installed Dichlorination System to dechlorinate all discharged water before it travels to navigable waters

- OEM installed sample station