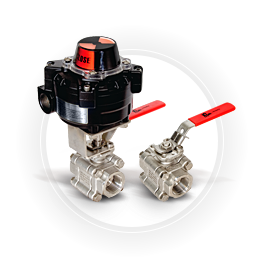

FPS 88 Series Valves ensure safety, reliability, and ease of maintenance. The valve features a three-piece body for ease of inline maintenance without breaking the piping connection and is available with NPT, socket weld, or butt weld ends, in sizes ¼” up to 2”.

All FPS valve designs utilize a triple-redundant stem seal. Stage 1 is via a pyramidal stem seal, stage 2 is via an O-ring and stage 3 is via multi-layered V-Ring Chevron™ Packing. The blowout-proof design is tensioned using Bellville washers for the ultimate in maintenance-free operation.

- Leak watch windows in all valve castings allow the user to check the stem seal for leakage.

- Visual indication of the ball orientation can be confirmed by way of a colored indicator that is visible in the leak watch window.

- FPS maintains stock of all valve components to allow for very quick deliveries.

FPS is a leader in reliable, cost-effective, high-performance shut-off valve technology. Our automatic and manual shut-off valves are installed around the world in pulp and paper, petrochemical, and power generation applications. FPS valves provide low maintenance, leak-proof, and fail-safe operation.

The FPS valve line was developed to meet our ongoing requirement for high-performance safety shut-off valves for use with gas and oil ignitor systems. When developing the valve line, our main criteria were to create a very high-quality valve package that would exceed the requirements of CSA and FM valve performance standards. FPS maintains significant inventory at our factory in Nova Scotia, Canada.

Customers requiring valves can expect quick quote turnaround, expert assistance with product selection, very short delivery times, and prompt submittal of quality assurance-related documentation.

Our custom-engineered valve trains are a perfect solution for customers seeking to reduce the cost of site-assembled equipment. FPS provides complete valve train engineering services including sizing all shut-off valves, strainers, pressure regulation valves, flow control valves, and instrumentation. Fuel valve trains are typically designed to CSA 149.1, CSA 149.3, ASME B31.1, and B31.3 along with customer specifications such as painting, material country of origin limitations, and special NDE requirements. A full quality assurance package is compiled including inspection, test reports, MTR’s, and weld maps. The fully assembled valve train is electrically wired, pneumatically tubed, pressure tested and all components are functionally tested prior to being crated for shipment.